https://ift.tt/7NeoFnt

SGH2 Energy and Yamanashi Collaborate to Drive Green Hydrogen in Fuji Five Lakes

Transforming Fuji Five Lakes into a Green Model for the Future

A groundbreaking collaboration between SGH2 Energy, a U.S.-based green hydrogen pioneer, and Yamanashi Prefecture of Japan is set to revolutionize the scenic Fuji Five Lakes region. With an ambitious plan in motion, the partnership aims to transform this renowned tourist destination, located near iconic Mount Fuji, into a sustainable “green metropolis.” Through the integration of cutting-edge green hydrogen technology, this initiative offers a bold vision for cleaner energy and smarter urban development.

The joint agreement, formalized on February 13th, represents a major step in creating a sustainable urban model not only for Japan but for the global stage. The project includes establishing a carbon-negative hydrogen production facility using SGH2 Energy’s proprietary Solena Plasma Enhanced Gasification (SPEG) technology. Utilizing local biomass and biogenic waste, this facility will generate high-purity hydrogen to power zero-emission fuel cell electric vehicles (FCEVs), including buses used by tourists, and supply clean energy for regional industries.

Governor Kotaro Nagasaki of Yamanashi Prefecture and Dr. Hiroshi Tasaka, Chairperson of the Fuji Five Lakes Metropolis Forum, were instrumental in guiding this partnership alongside SGH2 Energy’s CEO, Robert T. Do. Together, they aim to lay the groundwork for a sustainable energy future rooted in innovation and commitment to climate solutions.

How SPEG Technology is Shaping the Future of Hydrogen

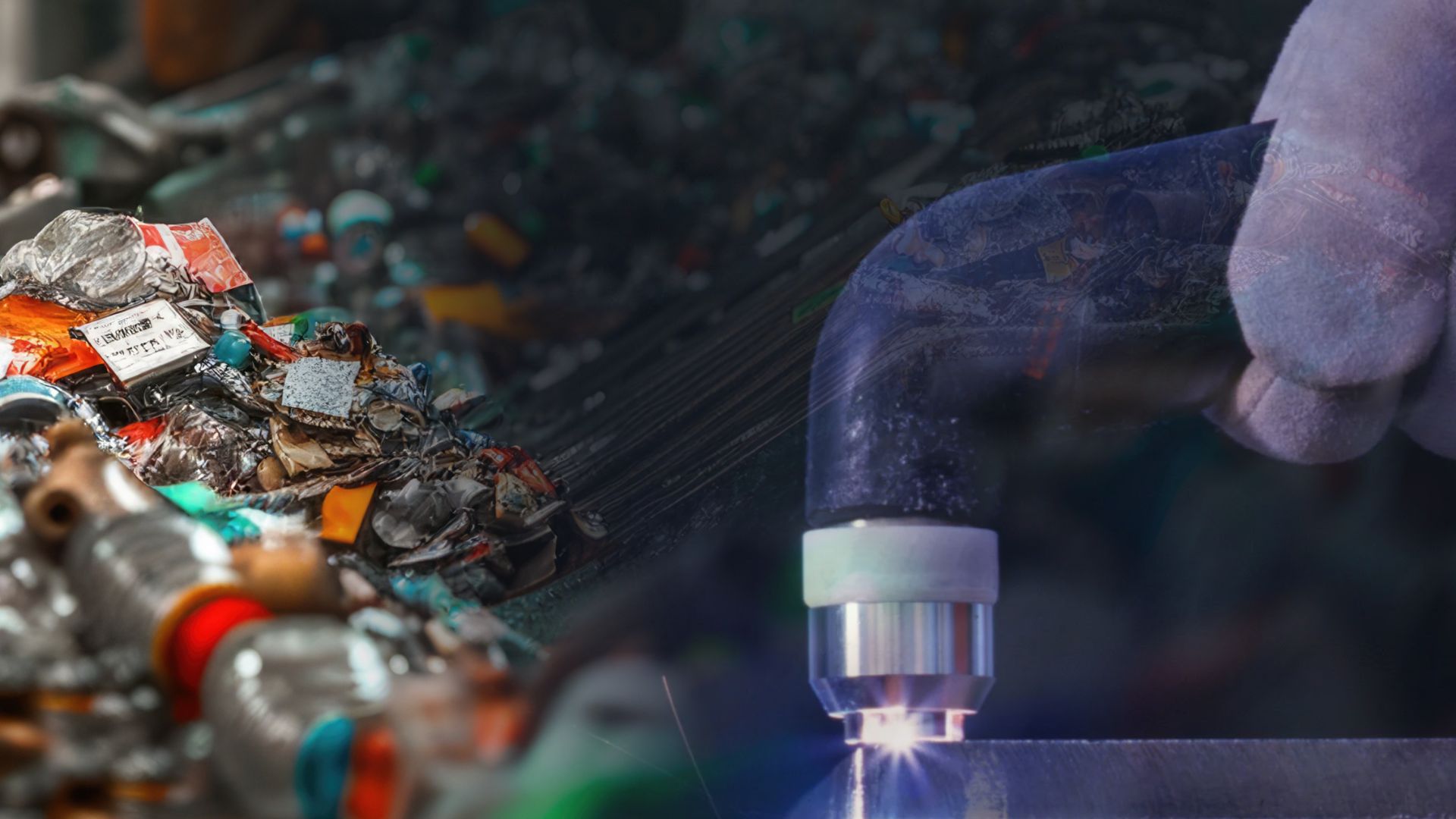

At the heart of this project lies SGH2 Energy’s game-changing Solena Plasma Enhanced Gasification (SPEG) technology. This process is unlike traditional hydrogen production methods that often depend on fossil fuels or expensive renewable energy. Instead, SPEG offers a cleaner, more cost-effective way to produce what SGH2 calls “greener than green” hydrogen.

But how does it work? The SPEG process involves heating waste materials to around 3,500–4,000 degrees Celsius using plasma torches. These extreme temperatures break down waste into its basic molecular components, creating a high-quality, hydrogen-rich biosyngas. This syngas then undergoes further processing to achieve a purity level of 99.9999%, making it ideal for use in vehicles powered by hydrogen fuel cells.

The technology goes beyond just energy production—it actively helps solve two urgent global challenges. By converting waste into clean energy, SPEG reduces pollution and eliminates harmful byproducts such as toxic ash. At the same time, for every ton of hydrogen produced, the SPEG process prevents up to 31 tons of greenhouse gas emissions, making it a pivotal tool in fighting climate change.

What This Means for the Fuji Five Lakes Region

For the Fuji Five Lakes area, the implications of deploying this technology are enormous. First and foremost, the project directly supports Japan’s carbon neutrality goals by cutting reliance on diesel-powered buses and other high-emission vehicles in this popular tourist destination. Visitors will experience cleaner air and quieter streets as hydrogen-fueled transportation systems roll out.

Equally important are the economic benefits. Using locally sourced biomass and organic waste turns the region’s resources into renewable energy, keeping infrastructure costs low while fostering energy independence. With SGH2’s modular plant designs, the hydrogen production facility can scale up rapidly to meet future demand.

Governor Nagasaki emphasized how this innovation represents more than just technological advancement. “The development of a carbon-negative hydrogen production facility is a significant milestone in our efforts to combat climate change, and it showcases the Fuji Five Lakes region as a leader in sustainable tourism,” he said.

SGH2’s Broader Vision and Global Partnerships

This partnership in Japan is one among several bold initiatives by SGH2 Energy. The company recently gained approval for its Lancaster, California, plant, which will be the world’s largest carbon-negative hydrogen production facility. By leveraging SPEG technology, this project will demonstrate the scalability of hydrogen as a cost-effective alternative to carbon-intensive fuels.

Furthermore, SGH2 is exploring ways to integrate artificial intelligence (AI) into its operations. Through a collaboration with global technology leader ABB, SGH2 plans to optimize its hydrogen production process using AI and digital solutions. This approach can enhance efficiency, reduce costs, and further streamline clean energy production.

International collaborations also play a key role in the company’s mission. SGH2 has partnered with entities in Korea to use hydrogen derived from plastic waste for next-generation fuel cell power plants. These steps underline SGH2’s broader vision of deploying its technology across diverse sectors, from transportation to heavy industry.

Why This Partnership Matters Now

The urgency behind this initiative stems from the mounting challenges of climate change and urban sustainability. Traditional energy sources are not only finite but also major culprits in global greenhouse gas emissions. Hydrogen, particularly “green” and “greener-than-green” hydrogen, has emerged as a clean energy solution for hard-to-decarbonize sectors, including transportation, heavy manufacturing, and even urban heating.

The Yamanashi-SGH2 collaboration could serve as a template for other cities and regions worldwide. By demonstrating the viability of localized waste-to-hydrogen systems, this project shows how clean energy can be more accessible and practical for diverse communities. The 2020s are shaping up as a pivotal decade for energy transformation, and partnerships like this one highlight the potential for big-picture solutions grounded in local action.

Applying Hydrogen Technology Today and Tomorrow

Although the timelines for large-scale hydrogen adoption vary, the technology is already being integrated into real-world scenarios. Facilities like the one being developed in the Fuji Five Lakes region offer immediate opportunities to replace diesel in public transportation, reduce energy costs for industries, and make tourism more sustainable.

Looking ahead, the ability to scale SPEG-powered hydrogen production will determine how rapidly it can impact broader sectors like shipping, aviation, and construction. With continuously improving technologies, such as AI optimizations and modular designs, the groundwork is being laid for hydrogen to progressively reshape global energy systems.

Ultimately, while hydrogen isn’t a one-size-fits-all solution, its versatility and clean profile make it a viable option for addressing today’s energy challenges. What’s happening in Fuji Five Lakes reminds us that sustainable progress begins with innovative partnerships and a commitment to bettering local communities, one region at a time.

February 18, 2025 at 10:05AM

https://ift.tt/kgc7D4S

Erin Kilgore