Harnessing AI For Materials

Integrating AI into research and development can accelerate materials development, and create sustainable, high-performance materials for the future.

Integrating AI into research and development can accelerate materials development, and create sustainable, high-performance materials for the future.

By Rishi Gurnani

In the rapidly evolving landscape of materials science, artificial intelligence (AI) stands out as a transformative force with the potential to revolutionize industries ranging from energy storage to nonwovens and fibers. Atlanta-based Matmerize Inc. — an early-stage company spun out of the Atlanta-based Georgia Institute of Technology — is on a mission to harness the power of AI to accelerate materials design and manufacturing.

The Transformative Power Of AI In Materials Science

AI is not merely a technological trend; it represents a paradigm shift in how materials science may be approached. By leveraging AI, vast datasets can be analyzed, material properties can be predicted with high precision, and complex processes that were previously reliant on laborious trial-and-error methods can be automated.

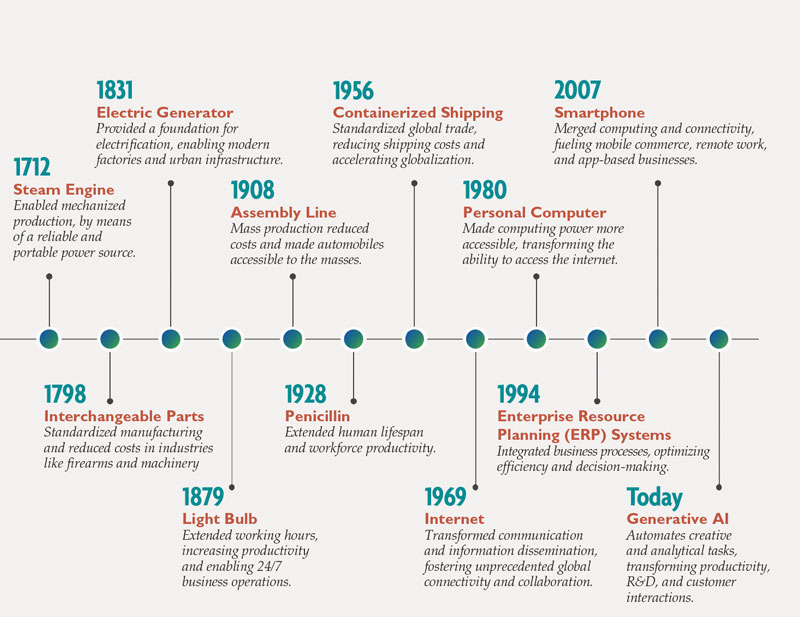

To fully grasp AI’s potential, it’s useful to draw parallels with other historical technological breakthroughs, shown in Figure 1, that have reshaped industries. The steam engine, introduced in 1712, revolutionized manufacturing and transportation by providing a reliable and portable power source. The light bulb extended productive hours beyond daylight, significantly enhancing productivity and quality of life. More recently, the internet has transformed communication and information dissemination, fostering unprecedented global connectivity and collaboration. Similarly, AI is poised to leave an indelible mark on the materials and nonwovens industries, driving advancements that were once thought unattainable.

Unique Advantages Of AI In Materials Science

AI offers several unique advantages that make it particularly suited for advancing materials science.

These advantages — the preservation of knowledge, high-dimensional learning and personalized search —are fundamental in overcoming traditional challenges in material design and manufacturing.

Preservation of Knowledge: One of the most significant benefits of AI is its ability to preserve and retain existing knowledge. Consider ChatGPT, an AI model trained on vast amounts of internet data, embodying a large portion of recorded human knowledge. When you ask ChatGPT a question, it draws upon the collective wisdom of experts embedded within its training data. Extending this concept to a corporate environment, AI can capture and retain the expertise of departing employees, ensuring that valuable institutional knowledge is not lost. Traditionally, when a valued coworker leaves, their expertise vanishes with them, forcing organizations to re-run experiments, train new hires from scratch, or accept the loss of critical insights. AI mitigates this by preserving knowledge within its models, providing continuity and reducing the costs associated with knowledge loss.

High-Dimensional Learning: AI excels in generating new knowledge, especially when dealing with high-dimensional problems that are beyond human cognitive capacities. High-dimensional learning refers to the ability of AI systems to process and analyze data with numerous variables and complex inter-dependencies. Historical examples like DeepBlue and AlphaGo illustrate AI’s prowess in mastering intricate domains such as chess and Go, where AI systems have surpassed human champions. In materials science, this capability translates to understanding and predicting the behavior of complex materials with numerous interacting components. AI can uncover patterns and relationships within high-dimensional datasets that humans might over-look, leading to the discovery of novel materials and optimized manufacturing processes that drive innovation forward.

Personalized Search: AI also revolutionizes the way we conduct searches by enabling personalized search capabilities. Unlike traditional search engines like Google, which provide generic results based on broad queries, AI can tailor search outputs to specific contexts and individual needs.

As an example, picture planning a surprise getaway for a loved one while juggling budget, interests and time constraints. Today’s AI tools can provide a personalize itinerary that captures a unique vision, transforming an overwhelming task into a heartwarming experience. Before, such detailed, bespoke planning often meant endless research across impersonal travel sites.

Similarly, in materials science, personalized search capabilities enable researchers to input highly specific requirements into AI models— reaction constraints, chemical inventories and supplier lists as just a few examples — receiving customized insights and recommendations that precisely match project goals and constraints.

Materials Informatics: Accelerating Material Discovery

The integration of AI into materials science has given rise to a specialized subfield known as materials informatics. This interdisciplinary approach combines machine learning, data analytics and materials science to develop structure-property models that predict material behaviors based on their chemical and physical structures. The genesis of materials informatics can be traced back to decades-old work in drug discovery, where AI models were employed to predict drug-related properties from molecular structures. This methodology has been success-fully adapted to polymers and other complex materials, enabling researchers to forecast properties like glass-transition temperature (Tg), mechanical strength and dielectric constants with remarkable accuracy.

Structure-Property Models: The Core Of AI-Driven Materials Design

At the heart of materials informatics are structure-property models. These models serve as predictive tools that estimate material properties based on structural characteristics. For polymers, this involves converting chemical structures into numerical vectors through so-called “fingerprinting” techniques. These numerical vectors are then fed into machine learning algorithms to forecast properties with-out the need for physical experiments. This capability significantly reduces both the time and financial investment traditionally required for material development. For instance, accurately predicting Tg can inform decisions about polymer selection and processing conditions, thereby streamlining the development cycle.

Advanced AI Techniques: Enhancing Model Accuracy And Efficiency

Developing reliable structure-property models necessitates sophisticated AI techniques, particularly when dealing with high-dimensional data and limited datasets — a common challenge in materials science. Three advanced approaches address these challenges:

- Active Learning: This iterative process begins with training an initial model on a small dataset. The model then identifies and designs new candidate materials, which are experimentally validated. The newly acquired data is added to the dataset, and the model is retrained, progressively refining its predictive capabilities. This method optimizes the learning process, ensuring that each experimental trial provides maximum informational value.

- Multi-Task Learning: Instead of developing separate models for each property, multi-task learning integrates datasets for multiple correlated properties and trains a single model. This approach lever-ages the inter-dependencies among different material proper-ties, enhancing overall model accuracy and enabling more comprehensive material design. For example, a single model could simultaneously predict both Tg and melting temperature, uncovering underlying correlations that improve predictive performance.

- Physics-Informed Learning: Traditional AI models often neglect established physical laws governing material behavior. Physics-informed learning integrates these laws into machine learning models, ensuring that predictions adhere to known physical principles. This hybrid approach marries the strengths of AI with the rigor of scientific theories, resulting in models that are not only accurate but also interpretable and reliable.

Matmerize: Empowering R&D Using AI

While AI offers unparalleled potential, its traditional implementation has been hindered by the need for specialized expertise. Matmerize aims to democratize AI in materials science by eliminating these barriers. Its software platform is designed to connect non-experts with advanced AI tools through an intuitive no-code interface, transforming raw experimental data into predictive models. This accessibility allows researchers to focus on innovation rather than the complexities of data management and model development.

The Matmerize software was developed with several key capabilities in mind:

- Hierarchical Structure-Property Modeling — Matmerize employs state-of-the-art algorithms to build hierarchical structure-property models that capture relationships across different physical length scales using proprietary fingerprinting techniques. In polymer science, for instance, models incorporate atomic triples, block-level descriptors, and chain-level features to predict properties like Tg with high accuracy. This multi-scale approach not only enhances prediction precision but also facilitates the exploration of complex materials such as copolymers, blends and crosslinked systems. By understanding how molecular structures influence macroscopic properties, researchers can design materials with tailored functionalities.

- User-Friendly Interface and Automation — The Matmerize platform is built with user experience at its core. The intuitive interface allows R&D teams to seamlessly navigate through data processing, model training, and prediction tasks. Automation features minimize the need for manual intervention, enabling researchers to generate predictive models in minutes rather than weeks. This efficiency accelerates the pace of innovation, allowing teams to iterate quickly and explore a broader array of material possibilities without being bogged down by technical complexities.

- Active Learning and Model Refinement — Matmerize incorporates active learning cycles to continuously improve model accuracy. The software suggests new experiments based on model predictions, which are then validated and added to the dataset. This iterative process ensures that models evolve with the latest data, maintaining their relevance and precision over time, even as key employees leave the organization. By facilitating continuous improvement, Matmerize helps organizations stay at the forefront of materials innovation.

Real-World Applications: Case Studies In Nonwovens

The following case studies illustrate the practical impact of AI in materials science and highlight how AI can facilitate significant advancements.

Case Study 1: Using AI To Discover High-Performance Dielectrics For Energy Storage Materials

Energy storage is a pivotal area with applications spanning defense, aerospace, transportation, and consumer electronics. Electrostatic capacitors, prized for their high-power densities, are integral components in these applications. Traditionally, materials like biaxially oriented polypropylene (BOPP) have been used as dielectrics in capacitors due to their favorable properties, including high breakdown field, low energy loss and cost-effectiveness. However, BOPP’s relatively low dielectric constant limits the energy density of capacitors, esp-cially at elevated temperatures.

Using AI models, Matmerize screened thousands of polymer candidates to identify materials with superior dielectric properties at high temperatures. These models predicted the energy density of polymers based on their structural features, enabling the prioritization of candidates with the highest potential. This targeted approach led to the discovery of new polymers, such as PONB-2Me5Cl, which achieved record-breaking energy densities at 200°C, a critical metric for aerospace and electric vehicle applications.1 These advancements demonstrate AI’s ability to help surpass conventional technologies.

Case Study 2: Designing Next-Generation 6G Materials With Resonac

As the telecommunications industry advances toward 6G technology, the demand for materials with specific electromagnetic properties has intensified. Tokyo-based Resonac, formerly Showa Denko, partnered with Matmerize2 to design materials optimized for 6G applications, where traditional design methods were proving inadequate in meeting stringent performance criteria.

Matmerize specializes in developing structure-property models that predict material behaviors with exceptional accuracy. Resonac evaluated Matmerize’s models against three third-party alternatives and found that its solutions provided superior predictive capabilities tailored to their specific needs. The enhanced accuracy of Matmerize’s AI-driven models enabled Resonac to streamline their material design process, reducing both the time and resources typically required for such specialized applications.

Impressed by the performance of the models, Resonac formed a strategic partnership with Matmerize to collaboratively design and develop new materials specifically for next-generation 6G technologies.

Case Study 3:Developing Biodegradable Polymers For Kimberly Clark

Sustainability is a paramount concern in the materials and nonwovens industries. Kimberly Clark, Irving, Texas, aimed to develop biodegradable polymers to replace conventional plastics, thereby reducing environmental impact without com-promising performance.

Matmerize’s software enabled Kimberly Clark to screen more than 20,000 biopolymer candidates, identifying more than a dozen promising chemistries with desirable mechanical properties. The AI models evaluated both the chemical structures and processing conditions, optimizing for performance metrics such as tensile strength and flexibility. The identified polymers currently are undergoing rigorous evaluation to ensure they meet Kimberly Clark’s sustainability and performance standards. This project highlights AI’s potential to drive sustainable innovation, enabling companies to develop eco-friendly materials that align with environmental goals.

Case Study 4: Streamlining Mechanical Recycling With Predictive Modeling

Mechanical recycling of plastics involves reprocessing materials into new products, a process that demands precise control over film composition and processing parameters to ensure both quality and consistency. Companies striving to align their recycled products with stringent government regulations must rigorously test their materials against the guidelines set forth by the Association of Plastic Recyclers (APR). Achieving certification from the APR is a formidable challenge, as it requires extensive and costly trials to validate that recycled films meet the high property standards necessary for certification.

Matmerize developed a predictive model for a client aiming to produce multilayer films certified by the APR. Its AI model could predict pass/fail outcomes based on film composition and processing parameters, significantly reducing the number of required experimental trials. By accurately forecasting which formulations would meet certification standards, the client could bypass tens or hundreds of expensive lab trials, saving both time and resources. Initial results have been promising, with the client benchmarking the Matmerize model against internal expert predictions and observing outstanding performance.

Building An AI-Ready R&D Organization

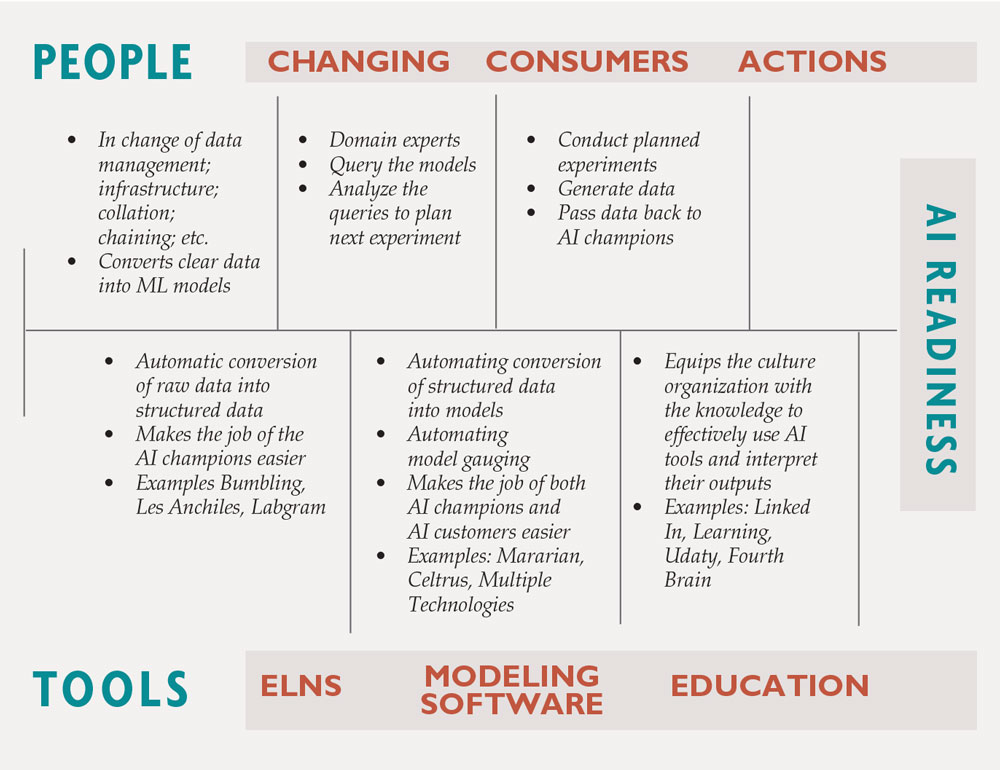

Integrating AI into research and development (R&D) is not merely a technological matter; it requires alignment at the cultural and organizational level (See Figure 3). Successful AI implementation hinges on robust data management, dedicated roles and strategic investments in key areas. In interactions with numerous companies, several critical elements emerge as essential for building an AI-ready R&D organization.

Data Management: The Foundation Of AI

Data is the cornerstone of all AI models. Effective data management involves collecting, organizing, and maintaining high-quality datasets that accurately represent the materials and processes under study. Common challenges include disparate data sources, inconsistent formats, and incomplete records. To address these issues, organizations should:

- Centralize Data Storage: Implement centralized databases or data lakes that consolidate information from various sources, ensuring easy access and consistency; and

- Establish Data Governance Policies: Define clear protocols for data collection, storage, and sharing to maintain data quality and compliance with industry standards.

Key Roles For AI Success

Building a competent AI-driven R&D team involves delineating specific roles that align with the organization’s AI objectives. Three primary roles are crucial:

- AI Champions: These individuals are responsible for managing and structuring data, ensuring that it is ready for model training and analysis. They bridge the gap between raw data and actionable insights, making them indispensable for AI initiatives.AI

- Consumers: These team members utilize the predictive models to inform decision-making processes. They leverage AI-generated insights to plan simulations, design experiments, and drive innovation.

- AI Actors: These are the hands-on researchers and technicians who execute planned experiments. They generate new data, feeding into the AI models and enabling continuous improvement.

Invest In Essential Tools And Training

Invest In Essential Tools And Training

To fully harness AI’s potential, organizations must equip their AI Champions, Consumers, and Actors with key tools and training programs:

- Electronic Lab Notebooks: The tools automatically convert raw data into structured data, easing the burden on AI champions.

- Modeling Software: Tools like Matmerize’s platform automatically convert structured data into easy-to-use models, easing the burden on AI champions and AI consumers.

- Training and Education: Provide comprehensive training programs to equip team members with the necessary skills and knowledge to effectively use AI tools and interpret their outputs. This ensures that all stakeholders can contribute to and benefit from AI initiatives.

Shaping The Future Of Materials Using AI

By enabling faster, more accurate material discovery and optimization, AI is driving innovation, reducing costs and fostering sustainability.

As the industry continues to evolve, embracing AI will be essential for organizations seeking to maintain a competitive edge and address emerging challenges. The integration of AI into R&D processes not only accelerates material development but also opens new avenues for sustainable and high-performance materials that meet the demands of the future.

References:

1 https://ift.tt/G95yIfh

2 https://ift.tt/J6cCnwa

Editor’s Note: Matmerize Director of Soft-ware Rishi Gurnani leads the development of AI-driven solutions for materials design and manufacturing. With a Ph.D. in Mate-rials Science and deep expertise in artifi-cial intelligence, he has collaborated with clients across various industries, including energy storage and nonwovens, to solve complex materials challenges using cut-ting-edge AI technologies. To learn more about the company, visit matmerize.com.

2025 Quarterly Issue I

February 27, 2025 at 07:46PM

https://ift.tt/3RrnZoP

Rachael Davis